MIG welding aluminum is a pretty complicated process, especially if it’s your first time. But you need a spool gun to get the job done.

Running aluminum wire through a regular MIG welder often turns into a big mess. Putting the spool of wire on a gun prevents the wire from getting tangled up in the line.

But even with a spool gun, many welders still struggle to work with aluminum. Some of the biggest problems come from a lack of preparation, as well as using improper methods. By following this in-depth guide, you can start welding aluminum with a spool gun in no time.

Understanding Aluminum Welding

Welding aluminum is difficult because of the metal’s physical properties. Aluminum is a soft metal that conducts heat very well, so it takes a lot of heat to get it to melt.

Most welders choose to TIG weld aluminum because it’s easier to direct a high amount of heat. But, the process is much slower.

Additionally, you need a similar filler material which is also very soft. But that presents another problem because the metal is too soft to push through a MIG welder lead.

This is where the spool gun comes into play. As you can see, aluminum’s unique properties present a real challenge to welders.

Key Characteristics of Aluminum

Aluminum is a non-ferrous metal that shares many similarities to copper and lead. It is soft and malleable, but it is also light.

Aluminum is a great metal to work with for special cases where both strength and weight are critical. But, a major problem with aluminum is that it’s more susceptible to cracking and wear than ferrous metals.

Challenges in Aluminum Welding

Aluminum has an oxide coat that requires a lot of heat to melt. In fact, the oxide layer requires way more heat to melt than the rest of the material.

That’s not all.

As you apply heat on aluminum, this metal will work against you and dissipate that heat.

Let’s not forget that aluminum is susceptible to cracking. That’s because of the rapid heating and cooling that occurs as you weld.

As you can see, if you want to weld aluminum, your work will be cut out for you, which often leads to material cracking. But with a little practice, you can weld aluminum with relative ease.

Choosing the Right Equipment for MIG Welding Aluminum

You need a couple of obvious tools when planning to MIG weld aluminum. The first is a MIG welder, but you also need a spool gun.

You also need a special MIG wire and shielding gas to work with aluminum.

To finish the list, ensure you have gloves, a welding helmet, welding tips and grinder wheels.

Selecting the Ideal Spool Gun

You won’t find a wide selection of spool gun options in a big box store.

Since aluminum welding isn’t a common type of welding, you’ll need to buy from a local welding supply store. You can also shop online for consumables like MIG wire and tips.

When selecting a spool gun, I recommend finding one that works with your welder. Try not to be too picky about brands, as there aren’t a lot of spool gun options available.

Remember that many low-end welders only have one spool gun option anyway.

Wire Types and Sizes for Aluminum Welding

When shopping for a spool gun, it’s also a good time to pick up some wire. There are two popular choices for MIG welding, which are ER4043 and ER5356.

You can use both for MIG welding – don’t forget to buy shielding gas.

The most common wire thicknesses are .030 and .035, so pick the one that matches your spool gun tips.

Also, get a small roll of wire to fit in the spool gun. Most spool guns need the 1lb. rolls of wire.

Differences between ER4043 and ER5356 Wire Alloys

Both ER4043 and ER5356 work to MIG weld aluminum.

But the ER4043 is a little softer and more resistant to cracking. In comparison, ER5356 is stronger but more brittle.

As a general rule of thumb, you can use ER4043 for most aluminum welding. It is easier to work with for beginners and isn’t brittle.

But ER5356 is better for critical jobs that need a very strong weld.

You should know the alloy of the metal you are welding. But that often isn’t the case if you are trying to make a repair.

In general, you want the number of the wire to match the metal’s alloy as close as possible.

Preparing for MIG Welding Aluminum with a Spool Gun

Like with all other MIG welding, the metal must be very clean in order to get a good weld. Failing to clean the metal leads to poor penetration and leaves a porous bead.

You can clean your aluminum the same way you’d clean other metals. But aluminum does need some extra prep before you start welding.

Cleaning and Prepping Aluminum Surfaces

Cleaning aluminum is pretty straightforward because the metal doesn’t rust. But, it does oxidize, so you should pay close attention to those areas.

For most aluminum, you can use a flap disc to remove debris like paint and oxidation.

Polished aluminum, however, is a little trickier. In that situation, use a Scotch-Brite pad on a die grinder.

Selecting Proper Shielding Gas

If you weld steel, you might have a tank of mixed gas that consists of some Argon. I don’t recommend using that gas for welding aluminum.

You need pure Argon to MIG weld aluminum.

But, there are a few other mixes you can use — including ones with Helium. Those mixes work for very special cases, but pure Argon is good for the average welder.

Importance of Pure Argon Gas

Aluminum requires pure Argon because Carbon Dioxide cannot be present. Adding Carbon Dioxide to your weld creates an unstable arc.

More importantly, it prevents the aluminum from melting the right way.

Importance of Preheating Thick Aluminum Parts

Because aluminum absorbs and dissipates heat so well, it’s difficult to steady the welder on one spot to make it melt. The solution to this problem is preheating the metal with an oxy-acetylene torch.

This is a necessary step, particularly for larger pieces of metal. Move the torch around the area that you plan to weld, but don’t heat it to the point it starts to melt.

Mastering Spool Gun Techniques for MIG Welding Aluminum

Now that you have everything prepared, it’s time to start welding. The MIG welding process is similar to other metals, but the clunky spool gun does take some getting used to. Additionally, you need to adjust speeds and feed settings for the material.

Push Vs. Pull

With most other types of MIG welding, push vs. pull comes down to personal opinions and preferences. But, you should push the bead rather than pull it to ensure that enough gas is ahead of the bead.

Pulling the bead, especially with aluminum, may lead to unnecessary porosity.

Optimizing Travel Speed and Angle

You need to weld at an approximate 20-degree angle. To put it in perspective, the tip of your nozzle should have a slight lean while still being upright. The travel speed is a bit more complicated for aluminum welding. You need to move much faster than you would with other metals, which does take some practice.

Adjusting Wire Feed Speed and Voltage

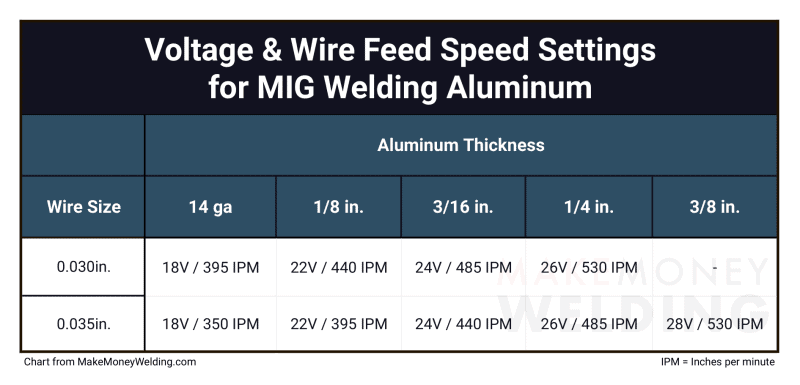

The weld settings for aluminum must be much higher than what you would use on steel. Some welder charts also list aluminum settings which is a good start. You also need to raise the pressure on your gas regulator to at least 35 CFH. Remember that you will need to raise and lower these settings once you run a test bead.

General MIG Welding Settings for Aluminum

Proper Stickout for MIG Welding Aluminum

Getting the right stickout means you are the proper distance away from the base material. The correct stickout for MIG welding aluminum is about ¾.” This is a little longer than most people use for welding other metals like steel, but it isn’t overly long. The reason for this length is that there is a high tendency for wire burn-back when welding aluminum.

Common Challenges and Solutions in MIG Welding Aluminum

Welding aluminum is a difficult process that even professionals struggle with occasionally. If you experience problems like a poor weld, don’t get disheartened.

Instead, carefully review your settings and look back at the above steps to ensure you haven’t missed anything. Like with all other welding, you need to practice patience when learning.

Overcoming Warping and Distortion

There are a couple of reasons that your metal may be warping and several ways to avoid the problem. The first is to make sure the metals you are welding are as close as possible so there is no gap to fill. Next, clamp the pieces of metal to a solid workbench if able. If your MIG welder has a pulse setting, you can try that too.

Preventing Burn-through

Burn-through is quite common on aluminum, despite it being good at transferring heat. The obvious reason that burn-through occurs is too much heat. Fix this by preheating the metal less. But it is actually better to turn the welder’s voltage down a bit or speed up as you run the bead.

Addressing Porosity Issues

There are two main reasons that you get porosity when MIG welding aluminum. The first is that there is a problem with the shielding gas. Determine this by turning up the CFH and running another bead. The second reason is that you didn’t clean the metal well, and contaminants entered the weld pool. Prevent this by cleaning the metal better.

Dealing with Black Soot Formation and Aluminum Oxidation

After running a bead, you may notice some soot built up around the bead. Usually, this will look like a brown or black smoke ring, which isn’t abnormal for some welding processes.

But, the area around the bead should be clean and not look like you just stick-welded a rusty old piece of steel.

Causes and Prevention

The most common cause of black soot and oxidation forming is the shielding gas. Test this by turning up the CHM on your regulator.

Some people need to get to 50 CHF to run a proper bead. If that doesn’t work, there’s a good chance you’re using gas with Carbon Dioxide.

Unfortunately, it is possible for tanks to get contaminated with Carbon Dioxide or other gases. While refilling tanks on the spot is pretty rare, this is an example of why swapping tanks is better.

But even a swapped tank can still have trace amounts of reactive gas that will cause problems when you go to weld.

Wire Storage and Handling Best Practices

Aluminum wire starts to deteriorate rapidly, just like the bare metal. This is because of oxidation.

So, it’s a good idea to take it out of the welder and store it in a Ziplock bag.

This is especially important if you don’t weld aluminum often. Impurities form on the wire quite quickly.

Not only does oxidation makes it difficult to work with, but it can also cause porosity.

Importance of Contact Tips and Their Maintenance

Contact tips are not only an integral part of feeding wire out of a MIG gun but are also where the electricity is transferred into the wire.

Because they play a big part in MIG welding, you must pay attention to keeping them clean and functional.

Preventing and Addressing Burnbacks

Burnback on a MIG welder is very frustrating. But, you can easily prevent it by keeping your extending the stickout. Additionally, you need to keep the nozzle of your MIG welder as clean as possible.

You may also experience burn-back because the wire isn’t coming out of the gun fast enough. Or, it’s coming out too fast to melt.

Reusing Contact Tips and When to Replace Them

As mentioned, it is important to keep your tips clean. But once a glob of molten metal fuses between the contact tip and the nozzle, you should replace the tip. Some people even choose to use an anti-spatter spray to keep burnback from damaging their tips.

Quick FAQs

What gas do you use to weld aluminum with a spool gun?

To weld aluminum with a spool gun, you should use 100% Argon. You should always use 100% Argon when Mig or TIG welding aluminum because it does not add carbon.

What size wire do I need for aluminum MIG welding?

You should match the wire size to the tip that your spool gun came with. Generally, you should use a .030 or .035 wire, but you may want to go a little bigger or smaller depending on the metal thickness.

Do you push or drag with an aluminum spool gun?

You always want to push the spool gun with aluminum because you are keeping the flow of air in front of the puddle rather than behind it. The shielding gas needs to be concentrated over the molten part of the metal.

Wrapping It Up

Hopefully, we’ve shined a light on MIG welding aluminum with a spool gun for you. While it isn’t as bad as some people make it out to be, it is still a challenge.

So don’t worry if your first few (or dozen) welds don’t come out great.

Work on setting a good pace and achieving good penetration, and the looks will improve too.

But remember MIG welding with a spool gun will always appear a little sloppy and never provide that “stacked dimes” look. For that, you need to learn to TIG weld aluminum.