Welding gas cylinders come in a variety of sizes – so how do you choose the right one?

Don’t worry; I’ll cover everything you need to know about gas cylinder sizes and the types of gases to use, so you know how to pick the right tank for your welding projects.

Plus I’ll also go over how to calculate how long a tank will last based on the flow rate and how much you weld.

Most Common Gases Used to Weld

Some of the main gases used to weld are Oxygen, Carbon Dioxide (CO2), Helium, and Argon. While some gases like Argon can be used on their own, it’s often best to use a combination of gases known as a mix.

Below are some of the most common gases and mixtures – and what they are used for:

- Argon: The gas is commonly used on its own to weld non-ferrous metals like aluminum and magnesium. It’s also used for TIG welding.

- 75% Argon + 25% CO2: This is one of the most popular mixtures for welding mild steel because it leads to a stable arc. But, you can also use it to weld stainless steel, although it is not ideal.

- 10% Argon + 85% Helium + 5% CO2: This mixture is commonly used in stainless steel because the Helium helps prevent the metal from oxidizing or rusting at a later date.

- Argon + Helium: Amix of Argon and Helium in varying quantities can be used to weld much thicker, non-ferrous metals. While Argon by itself will work to weld materials like aluminum, you can’t weld very thick pieces. Adding Helium makes the arc hotter, making it possible to weld thicker metals.

Related read: MIG Welding Gases – What To Use

Common Tank Sizes

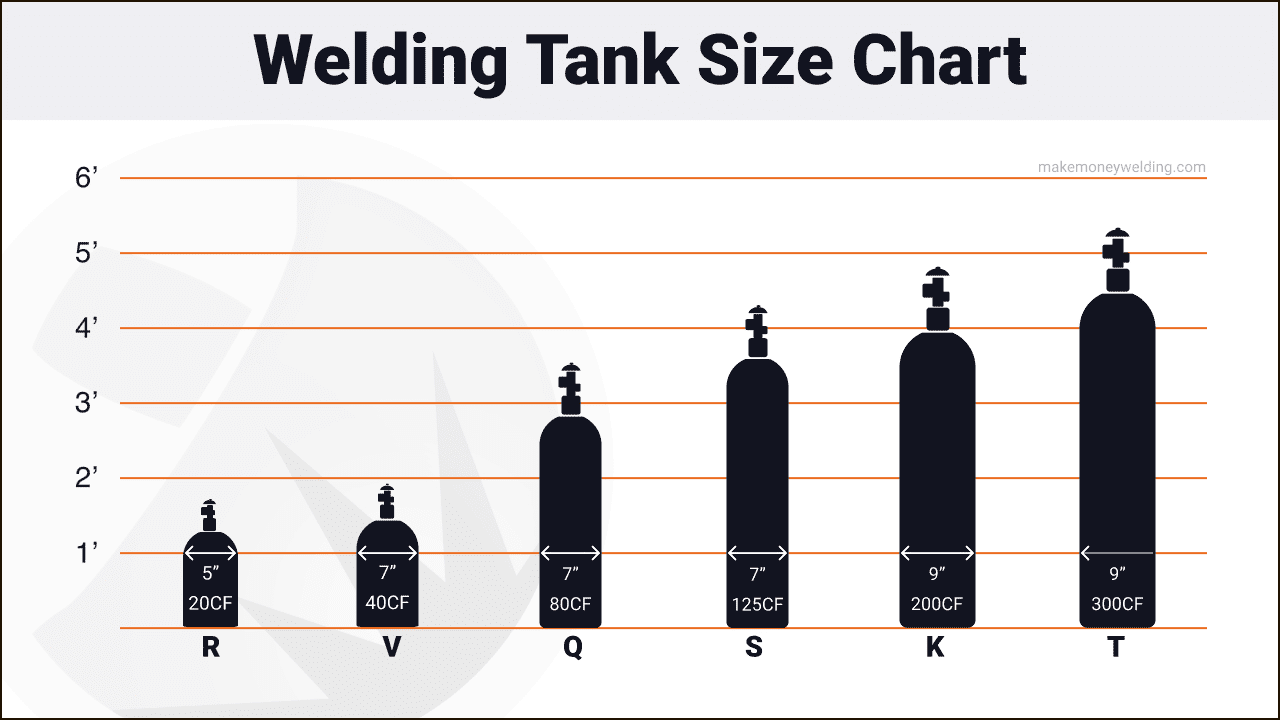

Shielding gas cylinders come in a wide range of sizes, and the price does too. But the most common sizes for hobbyists are 80CF and 125CF, while the most common sizes for professionals are going to be 200CF and 300CF.

Keep in mind that it is usually more affordable to get a large tank filled once rather than a smaller tank that requires multiple fills. Also, remember that you will have to be able to maneuver these tanks and transport them.

In the chart above, you can clearly see that there are two main tank widths. We don’t recommend using a 20CF tank because it will run out very quickly.

The only time that this would come in handy is if you have a compact inverter welder that is portable and you need a portable bottle to go with it. These small bottles are typically used for Oxygen or even Argon in HVAC and brazing work.

If you are a hobbyist or just starting out with welding, and you don’t have the room for a larger tank (or the budget), then you should opt for an 80CF or 125CF tank. These are both ideal to move around and can easily be picked up or rolled around on a welding cart.

You’ll be able to get a lot of small welds out of a 125 CF tank, so it should easily last a couple of months if you’re not using it constantly.

However, if you plan to do a lot of welding and don’t mind spending a little extra money upfront, then go ahead and get a 200CF or 300CF tank.

These take up a lot of room and are pretty heavy, but they’ll save you extra trips to get tanks filled, plus filling will be cheaper in the long run.

Check out the chart below for some important details on some popular tank sizes.

| Size | 40 cf (#2/V) | 80 cf (#3/Q) | 125 cf (#4/D) |

|---|---|---|---|

| Height | 22 in. | 35 in. | 45 in. |

| Diameter | 6.5 – 7.25 in. | 6.5 – 7.25 in. | 6.5 – 7.25 in. |

| Empty Weight | 24 lbs | 47 lbs | 58 lbs |

| Full Weight | 28 lbs | 56 lbs | 71 lbs |

| Full Pressure | 2015 PSI | 2015 PSI | 2265 PSI |

However, they are also available from online retailers, and they come full of gas.

Common Tanks for MIG Welding

Argon Tanks for TIG Welding

What Size is Right for Me?

Choosing the right tank comes down to budget, needs, and how much gas you will use.

Simply put, you should buy the largest tank that you can practically afford and will fit in your space. As previously mentioned, buying a larger tank means spending more money, but it’s a cost-effective option in the long run.

One good way to make larger tanks easier to handle is by keeping them close to the door.

On the other hand, medium-sized tanks like the 80CF and 125CF are good for most people because they are easy to lug around. Plus, you can throw it in the backseat or trunk of a car if you really need to.

Another consideration for medium-sized tanks is that they fit nicely on welding carts. While you can put bigger bottles on most carts, they will quickly overload the smaller ones.

Most people tend to use welding carts that have a spot for a gas cylinder. However, this isn’t always the best option.

If your workspace doesn’t move too much, or you do most of the welding at a workbench, put your gas cylinder in a fixed location and then run a hose to the welder. This keeps you from having to drag the bottle around and also means you can keep it in an ideal location for moving.

Finding an In-Between

Besides just buying a large tank, it also needs to be practical. Don’t buy a 300 CF tank if you are working alone and won’t have anyone to help you move it around.

Similarly, don’t buy one if you don’t have a truck to transport it in. However, large tanks are a good choice for people who do a lot of welding and would otherwise have to swap it every week or two.

A Quick Word on Small Tanks

Small tanks get a bad reputation, but this is primarily because professional welders do not like them. This is understandable because small tanks do run out of gas quickly, which can be annoying.

However, they do have their place, especially among hobbyist welders.

Both 20CF and 40CF are considered too small by many pro welders, but they are super easy to carry around. Combine those smaller tanks with an inverter welder, and you have the perfect portable setup.

How Long Will My Tank Last?

To figure out how long your tank will last, you need to first determine how much you are going to weld. In addition, you need to figure out how long you want to go between refilling.

It is also dependent on what your flow rate is set at. To determine exactly how long a tank will last, use the formula below.

Hours of use = size of the tank (CF) / flow rate (CFH)

To use an easy example, an 80CF tank with a flow rate of 20 CFH will provide about 4 hours of use.

Keep in mind that this is the amount of time that you are laying a bead down and the trigger is pulled rather than the number of hours that the welder is powered on.

With a 125 CF tank and a flow rate of 15CFH, you can get well over 8 hours of weld time.

While these numbers should be pretty close, real-world variables will affect the exact amount of usage you get.

Each gas reacts to the environment differently, and the pressure in the tank can actually go up or down depending on the temperature around it.

Additionally, you will go through gas faster if your welder has pre and post-flow settings enabled.

How Much Gas is Left in My Tank?

Figuring out how much gas is left in a tank is a little tricky, depending on the gas that is in it. For most gases and mixes, you can look at the gauge to see how much pressure it still has.

Most tanks hold a little over 2,000 PSI. So you can use that as a starting metric to determine how low the tank currently is.

The pressure will drop down to zero when it is empty, so you can use numbers in between to get a percentage left. For instance, 1,000 PSI on the gauge means the tank is about 50% full.

Keep in mind that most regulators have two gauges, with one reading in PSI which is how much pressure is left in the tank.

The other gauge will usually show L/min, which is how much gas the regulator is letting through. Instead of a second gauge, you may have a flow meter which uses a small ball in a cylinder to determine the flow rate.

When your tank starts getting low, you will also have to open the regulator more to compensate for the drop in pressure pushing the gas out.

The CO2 Exception

One gas that you cannot use a gauge with is CO2 because it has some unique properties. When you get a tank of CO2, it will look full on the gauges, but as you get close to the end, it will drop much faster.

To keep track of how much gas is left in the tank, you can use a scale to keep track of its weight.

Start by weighing an empty tank and then subtract that from its current weight to determine how much gas you have left.

Fortunately, if you have CO2 mixed with another gas, you don’t have to go through all this trouble. So, tanks with CO2 and Argon will still show up correctly on a gauge.

To signify a difference, CO2 tanks have different threads than other tanks like Argon ones. This is also done in part because a different regulator is required.

CO2 gets very cold, so it requires a regulator that can hold up to frigid temperatures. You should never use adapters to go from a CO2 tank to a non-CO2 regulator.

FAQs

How big is a 125 Argon tank?

A 125 CF Argon tank is about 45” tall to the top of the knob and 7” round. The tank weighs 58 lbs empty and 71 lbs filled, so it is manageable for one person to move around. Like most tanks in this size range, it holds about 2,265PSI.

How long will a 40 CF argon tank last?

The length of time a tank lasts is dependent on what the flow rate is set at. But, 20 CFH is a good average. Assuming a 40 CF tank at 20 CFH (40CF/20CFH), you will get about 2 hours of use.

How long will a 20 CF argon tank last?

A 20CF tank won’t last very long and really isn’t the best choice for most welders. At an average flow rate of 20 CHF, you can expect the tank to only last one hour (20CF/20CFH=1 hour).

Wrapping it Up

By now, you should have a better idea of what size welding gas tank to purchase.

Just remember to get the largest cylinder that is both practical and within your budget. You should also factor in your amount of usage so you don’t get something that is either too small or way too big.

One other thing worth mentioning here is that most gas retailers will allow you to swap for a different type of gas.

This could really come in handy if you end up with a project where you need a different type of gas but don’t want to buy another tank.

Similarly, you can get a small or medium-sized tank to start with and later upgrade to a larger tank. Then, swap the smaller tank for a different type of gas that you may use less often.