If you want to get a strong weld, you’ll need the right welding gas.

MIG welding requires a shielding gas because it does not use flux in the wire, the way flux core welding (FCAW) does.

The problem is the wide range of gases and mixes to choose from for welding. And if you don’t have experience as a welder, you’ll struggle to pick the right one.

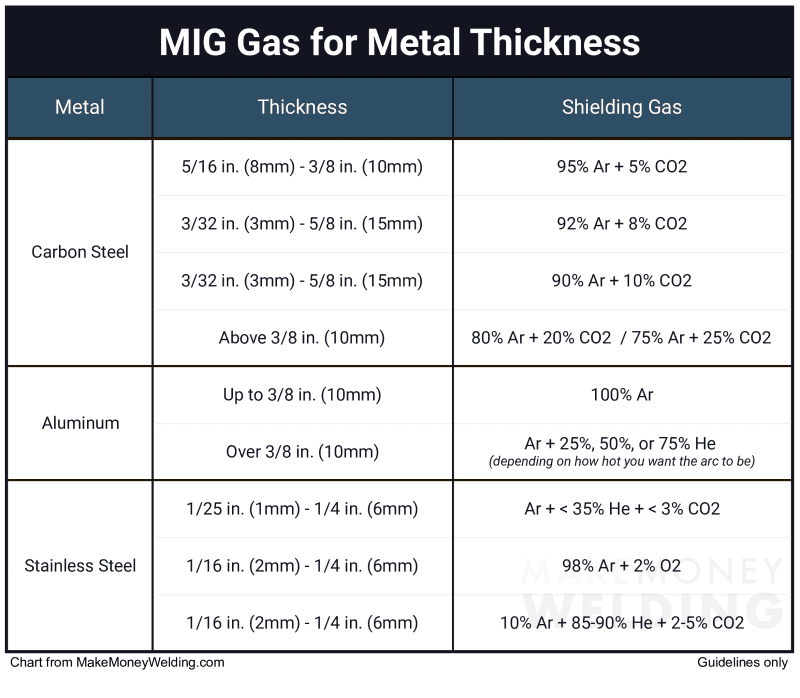

Keep in mind that different metals require different types of shielding gas. Even the thickness of metals and personal preferences can play a part in which shielding gas someone uses.

Read on to learn about the most commonly used gases for MIG welding, how to select a blend for a specific welding task, and why I recommend a 75% argon and 25% carbon dioxide blend for welding mild steel.

Gases Commonly Used for MIG Welding

Four welding gases are commonly used for MIG welding: argon, carbon dioxide, oxygen, and helium.

There are also blends of these gases available, each with a specific purpose. Therefore, it is possible to use certain gases for different materials.

However, some gases are better suited for certain tasks than other blends. So, you should look at each and consider how they fit your intended use. You may need to consider if you’ll need more than one type of gas, or not.

Argon

Argon, or a blend of it, is usually the best choice for most MIG welding applications. It’s affordable for hobbyists and creates a very clean weld. It also produces a very stable arc, and its spatter is manageable.

The downside to argon, however, is that it produces a relatively narrow weld, which is why it is commonly blended with other gases.

But, having 100% argon is beneficial if you also plan to weld non-ferrous metals such as aluminum or use a multi-process TIG welder.

Carbon Dioxide (CO2)

Carbon dioxide is a very popular shielding gas among hobbyist welders. It is typically the most affordable option and does a pretty good job welding most ferrous metals. Carbon dioxide is unique because it is the only reactive gas commonly used for MIG welding that can be used on its own, meaning it is not an inert gas and does not need to be mixed with one.

This makes the weld stronger by allowing for more penetration on thicker metals. The problem is that the arc is less stable than it would be with an inert gas, which could be problematic for those new to MIG welding. Also, you cannot use it to weld non-ferrous metals.

Oxygen

Oxygen is similar to carbon dioxide in that it is also a reactive gas. However, it cannot be used on its own. Instead, a small amount of oxygen can be added to other gases to help produce a better arc and improve penetration. The most common use for oxygen is welding steel when combined with argon. It cannot be used with non-ferrous metals such as aluminum or magnesium because it can cause oxidation.

Helium

Helium is another inert gas that shares some similar properties to argon. However, helium is commonly used with non-ferrous metals when blended with argon. The benefit of helium is that it produces a hotter weld, leading to more penetration. It can also speed up the welding process since it does produce a stronger arc.

The downside to helium is that it is a lightweight gas; just like a balloon, it will quickly rise. To compensate for the rising helium, you must increase the flow rate considerably, which means you will go through it much more quickly than other gases.

Blends

There are plenty of welding gas blends available, but if you are starting out, then it is best to stick to one of the common blends. If you aren’t sure which is best for your application, try to get your gas from a welding supply house, as they will be able to better help you choose the right one for your application.

- A 75% argon and 25% carbon dioxide blend, commonly referred to as 75/25, is the best choice for most steel applications.

- A 10% argon, 85% helium, and 5% carbon dioxide blend is the most popular tri-mix gas and is used for various steel applications.

- A 75% argon and 25% helium blend is suitable for welding thick, non-ferrous metals such as aluminum. Increasing helium content will produce better welds for thick metals.

Selecting the Right MIG Shielding Gas for Task at Hand

There are three factors to consider when choosing a shielding gas:

- Metal type: While some gases work for various types of metal, it is best to narrow it down and choose the one that will work best for a specific application.

- Metal thickness: You need to consider how thick the metal you plan on welding is, as certain gases lend themselves better to thicker material.

- Budget: Although most shielding gas is relatively affordable, you should consider how much you’re going to need and how much the tank will cost.

Metal Type

The type of metal you intend on welding should be the main factor when choosing a welding gas. This is because different materials react very differently to shielding gas, and some perform better than others.

Carbon Steel

The best choice for welding carbon steel is usually a 75% argon and 25% carbon dioxide blend. It is the most versatile for a range of thicknesses as it does provide good penetration. You can also get lower amounts of carbon dioxide depending on the thickness of the steel you plan to weld.

Using 100% argon will lead to an unstable arc, making it very difficult to weld. Conversely, 100% carbon dioxide will work for thicker steel but easily blow through thinner materials.

Aluminum

A common misconception with aluminum welding is that the gas doesn’t matter as much if you use a spool gun. This is incorrect, as a spool gun still requires specific welding gas. While you can weld steel with 100% argon, you cannot weld aluminum with carbon dioxide or oxygen.

Therefore, 100% argon is likely your best choice for most aluminum applications. Another good choice is a 75% argon and 25% helium blend, particularly for welding thicker aluminum pieces. Helium is suitable for welding thick aluminum because it does aid penetration.

Stainless Steel

Stainless steel is probably the most complex and confusing metal to choose gas for as it shares many similarities with carbon steel while having its own unique properties. You can go with either a two-gas or a tri-mix blend for MIG welding stainless steel, but it really comes down to personal preference and what else you plan to weld with the gas.

The ideal gas blend for stainless steel is a tri-mix of 85% helium, 10% argon, and 5% carbon dioxide. The percentages can vary slightly depending on local availability. You may also need different blends depending on your situation and the exact type of stainless steel you are working with.

Not all stainless steel is the same, and many intricacies go into using the correct gas, especially on critical jobs.

However, a two-gas blend will be sufficient for most hobbyists or those doing non-structural work with stainless steel. You can use 75% argon and 25% carbon dioxide, the same mix as carbon steel. The only downside is that it can leave carbon in the weld, so the joint won’t be corrosion-resistant. You could also use a mix with a lower carbon dioxide content to combat this.

Metal Thickness

You should also consider the thickness of the metal you intend to weld. If you plan to primarily weld thicker materials, you may want a gas that provides more penetration. Similarly, you could choose a gas that does not create as much penetration if you are mainly working with thinner metals.

Most users work with various metal thicknesses, so it is usually better to choose a versatile blend like 75% argon and 25% carbon dioxide, which will work for a wide range of applications.

Budget

Your budget is another major factor to think about. Fabrication shops will have multiple types of gas on hand for the different types of metal they work with.

However, you shouldn’t spend a fortune on gas if you are just starting.

Instead, choosing a gas that will work for most of your needs is best. The cost to refill gas cylinders is usually pretty close for most of the options we covered.

However, the cylinder cost will make it cost-prohibitive to have numerous tanks on hand.

Related: Welding Gas Tank Sizes Explained

100% Argon:

| Size | Initial Cost (full) | Refill |

|---|---|---|

| 40CF | $230 – $260 | $45 – $60 |

| 80CF | $290 – $320 | $55 – $65 |

| 125CF | $350 – $390 | $70 – $85 |

75% Argon + 25% CO2:

| Size | Filled Tank | Refill |

|---|---|---|

| 40CF | $240 – $280 | $45 – $60 |

| 80CF | $290 – $330 | $55 – $65 |

| 125CF | $350 – $390 | $70 – $85 |

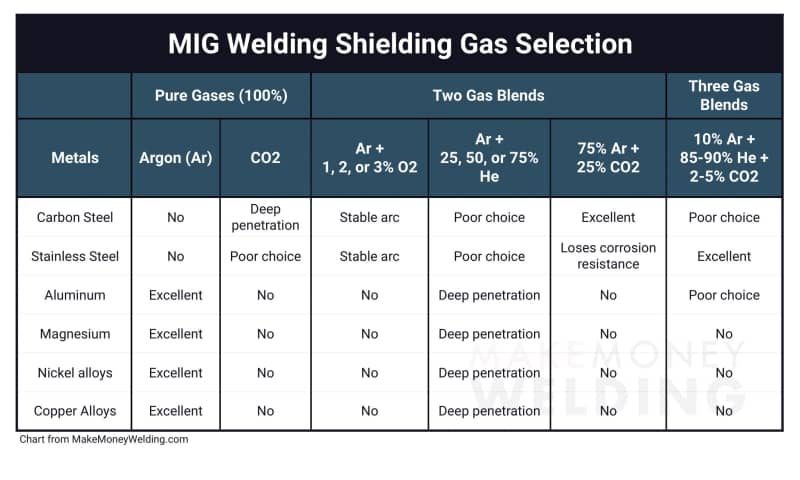

MIG Shielding Gas Selection Chart

Now that you have a better idea of the types of welding gas available for welding a range of metals, it is time to choose which is right for you. There is no one size fits all welding gas; however, some are more versatile than others.

To provide a better picture of which welding gas to choose, take a look at our chart, which compares some popular gases with types of metal. This should give you a pretty good idea of which gases have overlapping uses:

FAQ

What is the best gas for MIG welding mild steel?

The best gas for MIG welding steel is a 75% argon and 25% carbon dioxide blend.

Can you MIG weld with 100% argon

Yes, you can MIG weld with 100% argon (which is a good choice for MIG welding aluminum). It is also possible to MIG weld steel with 100% argon, although you may not achieve the best results.

Do you need gas to weld aluminum?

Yes, you generally need gas to weld aluminum because there is no flux-cored wire designed for welding aluminum. However, MIG welding aluminum is already pretty complicated, and aluminum has some unique properties that do lend themselves to flux core welding.

Why is argon used in MIG welding?

Argon is used in MIG welding because it is an inert gas that removes other gases from the molten weld puddle. In doing so, it removes impurities and prevents porosity in the weld pool that would occur if it was exposed to atmospheric gases.

Wrapping It Up

Choosing a gas for MIG welding can be quite overwhelming if you are just trying to get started. However, most welders tend to go with a 75% argon and 25% carbon dioxide mix if they are primarily welding steel or even some stainless steel.

In comparison, 100% argon is also a good choice if you mainly want to weld aluminum or intend to use the same gas for TIG welding. If you are still unsure which one to choose, it is a good idea to consult with someone at a welding supply house or a gas supplier.

Be sure also to check prices on gas with multiple suppliers, as prices and terms can vary wildly. In some cases, it may make sense to lease a bottle, while at other times, it makes sense to purchase one outright. You can even purchase bottles online or at big-box retailers, but make sure a local gas supplier will swap the tanks.

Also, consider how much each supplier charges for refills, as each company tags its bottles to prevent you from swapping them elsewhere. No matter which gas you start with, most gas suppliers will let you swap for a different gas type on your following exchange.