If you’re new to welding and you’re wondering “what is weld porosity” and how do I fix it…

… I’m going to show you this and much more in this article.

I see more instances of weld porosity with MIG welding, and it’s simple why that is. With MIG you’re using a shielding gas that can easily be blown away.

Here’s why that’s a problem…

In any welding process, whether it’s learning TIG welding, learning MIG welding, or learning stick welding you’ve got to protect the molten hot weld puddle from the atmosphere.

When you’re welding with a stick welder (SMAW) your welding rod is covered in flux.

This “flux” is what protects from welding porosity.

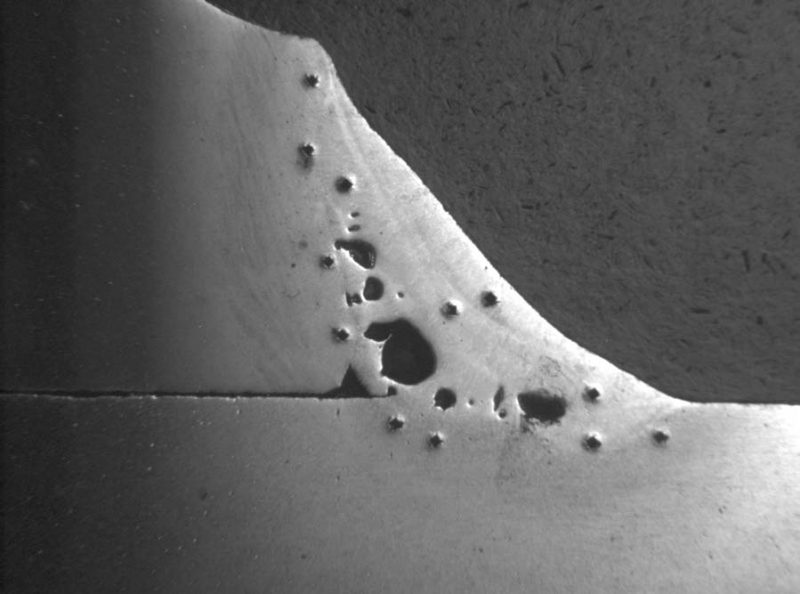

If you were to weld without the flux coating on a welding rod, nitrogen and oxygen in the atmosphere would get trapped in your welds causing tiny pinholes. These act to weaken your welds.

How To Avoid Weld Porosity When MIG Welding

Weld porosity occurs so often with beginner MIG welders because of several reasons:

1: You aren’t keeping the MIG gun at the correct angle when welding.

You should try to maintain about a 15 degree angle with your MIG gun. Laying the gun over too far will cause you to lose gas coverage, and can even bring in more atmospheric gases. When using the GMAW, FCAW, or SMAW processes remember to angle the gun and the electrode at around 15 degrees.

2: You’re out of gas

This might seem like an obvious mistake, but when you’re in the middle of a project and time slips by you, you’ll forget to check your tank levels. Once you run out of gas, then you have no gas coverage whatsoever, and your welds will have pinholes and wormholes all throughout. At this point, you have no option but to grind out those welds and lay new ones.

3: Your MIG hose is pinched

Whether your feeding a new spool of wire through your machine, or your laying a weld, having any sort of impedance will keep the wire (or gas) from making it to the gun. Make sure your line isn’t being pinched, and if you’re adding new wire then try to keep the hose as straight as possible to avoid any hangups.

[coursead]

4: The gun is too far away from your workpiece

You should try to keep your MIG nozzle about 1/4″ to 1/2″ from the workpiece when welding. You can get away with a little more distance if you’re close to burning through, but I wouldn’t recommend going over 3/4″. Place your hand about 1 inch in front of your MIG nozzle and pull the trigger as a test. You should feel the gas blowing, but if you move it farther away you’ll notice that you don’t feel it anymore.

5: Your MIG nozzle is clogged

Your MIG nozzle will easily get clogged with weld spatter. This is why you need a good pair of MIG pliers to scrape out your nozzle periodically. Too much spatter build up will impede the shielding gas, resulting in weld porosity. There is also nozzle dips you can buy to keep the weld spatter from sticking to your MIG nozzle.

6: Your shielding gas is being blown away

Make sure you aren’t using your MIG welder in front of a shop fan, or where a breeze can blow it away. If you’re going to be using a wire welder in a windy area, make sure you use flux core wire. You’ll dramatically reduce your chances of weld porosity.

7: You didn’t properly clean your metal

If your metal is oily, greasy, and even rusty it will release gasses that reduce the weld penetration you get in the metal when welding. It’s recommend that you hit your workpiece with a grinding wheel or wire wheel.

8: Your regulator is broken

If you’re having inconsistent gas coverage, it might be the result of a faulty regulator. Check that the gas is coming out of the nozzle at a constant rate by holding your hand about 1 inch in front of the nozzle and pull the trigger.

If you’re looking for a clean welding process for beginners, then don’t overlook MIG welding.

MIG produces super clean welds because there is no flux involved when you’re welding with a shielding gas.

When you lay a MIG weld, you have nothing but pure metal left after the weld.

There is no chipping or scraping involved. However, you may have heard that wire welders produce slag, and that’s true if you’re using it with flux core wire.

Here’s an example of the slag coating produced by flux.

The wire actually has the flux inside of the wire, and when the metal is melting it produces a slag coating.

While flux core produces great, strong welds, some people prefer to use MIG only. And you should if you’re welding on projects that require you to have super clean welds.

I hope this helps you solve any problems you’re seeing with weld porosity.