It is crucial for beginner MIG welders to understand how MIG welding gas pressure functions in order to create good welds. Every welding job requires you to adjust the proper flow rate for the task.

If the shielding gas flow is insufficient, your welds will be brittle and prone to porosity and oxidation. If the shielding gas flow is too high, things could worsen.

Because of that, finding a balance between the flows is key for a good weld. The flow rate depends on several factors, including the material you’re working on.

Read on to learn more about the differences between gas pressure and flow rate, the flow rate minimum and maximum settings, and how to use them during MIG welding, correctly.

Pressure vs. Flow Rate

Many people confuse gas pressure with gas flow rate. However, these are two entirely different terms with separate functions.

The gas pressure is an essential factor that affects the overall quality of your welds. It’s measured in pounds per square inch (PSI) and is crucial for making high-quality, reliable welds.

The amount of gas pressure you’ll need for MIG welding will differ based on the material you’re welding. However, it’s typically between 3 and 8 PSI.

The gas flow rate determines the amount of gas that goes through your torch to the weld, controlling the thickness of the weld bead. It’s measured in cubic feet per hour (CFH) and is one of the main MIG welding settings for successful welds.

If your gas flow rate is too low, it will result in a weak weld, while a high flow rate will make your weld too thick.

It’s common for welds to become prone to oxidation and porosity if there’s insufficient gas flow. Because of that, for MIG welding, you must use an adequate gas flow and provide enough shielding gas for your welding puddle.

Otherwise, your welds will be brittle and weak — and you don’t want that.

Different Types of Pressure Gauges

You can typically encounter standard gas regulators and higher-quality regulators (flowmeters).

Gas Regulators

Most common regulators contain two gauges — one shows the gas flow rate, while the other shows the pressure inside the gas tank.

The pressure gauge:

- Showcased in PSI (pounds per square inch)

- Ideally, the pressure for MIG welding should range from 3 to 8 PSI

The gas flow rate gauge:

- Showcased in CFH (cubic feet per hour)

If you have a standard gas regulator, opening the valve will release the gas, moving the needles inside the gauge to represent the gas flow rate in CFH.

Flowmeters

Flowmeters, often known as higher-quality regulators, are more modern than standard gas regulators. Instead of having two gauges like common regulators, flowmeters have one gauge displaying the pressure.

However, they also feature a vertical plastic chamber that replaces the second gauge showing the gas flow rate.

What a Flowmeter Tells You vs. a Pressure Gauge

As I mentioned earlier, standard regulators have two gauges that display the pressure in the tank and the gas flow rate.

When handling a common regulator, you release the gas by opening the valve, which moves the needles in the gauge showing you the gas flow rate in CFH. These regulators are typically precise, although the mechanism could malfunction, and the needles could get stuck.

Flowmeters are higher-quality products, and they function a bit differently than standard regulators. The gauge on the flowmeter shows the pressure inside the tank, while the vertical plastic chamber indicates the outbound shielding gas flow rate.

The chamber design showcases measurements in CFH, with a metal ball inside of it. The metal ball rises due to the pressure as the gas flows through the chamber.

When handling a flow meter regulator, you need to open the valve to increase the gas flow rate.

However, this type of regulator is much more reliable as you can also look at the ball in the chamber and verify that it’s floating at an adequate level.

The mechanism uses gas pressure and gravity to show the gas flow rate, which is more accurate than common regulators.

Is Every Gas Measured the Same?

Not every gas is measured the same. Every shielding gas has different properties, which makes some gases heavier and denser than others.

Because of that, your regulator must match the gas in your tank, or you’ll get an inaccurate reading.

This is not that important for MIG, as argon and carbon dioxide have similar properties, but it’s still something you should keep in mind.

Carbon Dioxide Has Special Challenges

When using a 100% carbon dioxide tank, you’ll need a specialized regulator rated for carbon dioxide. This is because carbon dioxide has a low temperature, so a gas flow meter or a regulator could freeze as the gas expands.

While most people don’t get a chance to experience a total regulator freeze, they still notice a frost build-up that occurs over time.

It’s also important to note that welding gas bottles for gases other than carbon dioxide uses a CGA-580 connector, while carbon dioxide tanks use CGA-320.

As CO2/Ar regulators are threaded for CGA-580, using them for a carbon dioxide gas tank will require you to have a CGA-320 to CGA-580 adapter.

Related: Choosing the right size welding gas tank

Why Is the Flow Rate Important?

The flow rate affects your welds’ quality and integrity, so keeping it at an adequate level is essential.

Maintaining a proper flow rate of your shielding fluid will protect the weld puddle from atmospheric contaminations while strengthening the weld joint and preventing possible defects.

Using the improper flow rate is a dangerous mistake common for beginner MIG welders. Because of that, it’s crucial to learn how to adjust the flow rate properly.

If you use an inadequate flow rate, you’ll risk brittle welds and possible atmospheric contamination, which leads to oxidation. You could also experience excess spatter and porosity.

Using a higher flow rate than needed also means your costs will be higher as you’ll waste more gas than needed.

The Impact of Shielding Gas Flow on Weld Quality and the Proper Rate Varies

The primary purpose of the shielding gas during MIG welding is to protect the weld pool from atmospheric contamination. It also affects the efficiency of the whole welding process and the quality of your weld.

When there’s insufficient shielding gas, your weld could suffer from porosity and oxidation and become brittle. Similarly, when you use a higher shielding gas flow rate than supposed to, your welds would be too thick.

In MIG welding, you’ll typically come across shielding gases that include:

- 100% Ar

- 100% CO2

- 75/25 Ar/CO2

- Tri-mix (10% Ar, 85-90% He+ 2-5% CO2)

- Ar + 25%, 50% or 75% He

Read: Best Gas For MIG Welding

Each shielding gas affects the welding process differently based on its characteristics. Because of that, you should ensure you’re using a suitable shielding gas for the material you’re welding while also using an adequate nozzle and diffuser.

When it comes to the gas flow rate you should use, it will vary based on multiple factors, with the material and the nozzle size being the main ones.

The proper gas flow rate for MIG welding can vary but is typically between 10–30 CFH, although it can be much higher, up to 50 CFH.

Minimum and Maximum Flow Rates

Every shielding gas has maximum and minimum recommendations for the gas flow rate. In MIG welding, it’s essential to know more about these rates and find a sweet spot that will make your welds reliable and durable.

Going overboard in both ways could cost you the whole weld, which is why you need to ensure you’re using a proper gas flow rate when welding.

Minimum Flow Rates:

The minimum shielding gas flow rates will vary based on the welded material and the environment you’re welding in. Regardless of your working conditions, the gas flow rate you use shouldn’t be lower than 10–15 CFH.

Here’s a quick reminder of the minimum flow rates based on the material:

- Steel: 10 CFH

- Aluminum: 20 CFH

- Stainless steel: 20 CFH

As for the effect on the environment, working outdoors commonly means you’ll need to use a higher shielding gas flow rate than when welding indoors.

Maximum Flow Rates:

The maximum shielding gas flow rate is equally important as using a gas flow that’s too high could lead to turbulence, and damage your weld. While the minimum rates depend on the environment and materials, the maximum gas flow rate depends on the nozzle size.

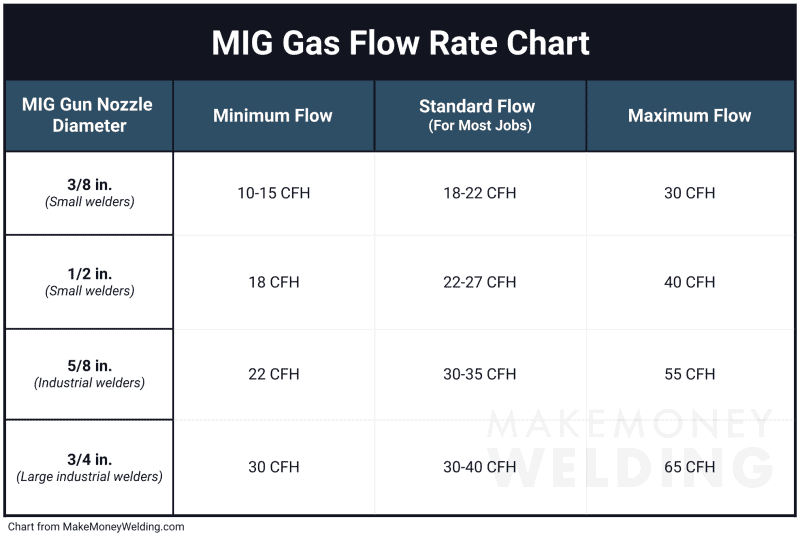

Here’s a quick reminder of the maximum flow rates based on the nozzle size:

- ⅜ inches: 30 CFH

- ½ inches: 40 CFH

- ⅝ inches: 55 CFH

- ¾ inches: 65 CFH

Recommended Flow Rates for Some Common Metals

Steel, aluminum, and stainless steel are some of the most common materials for MIG welding. Each material has specific flow rates depending on the travel speed, the nozzle diameter, the wire feed speed, and the mill scale amount on the material or the degree of oxides.

Steel

Mild steel is one of the easiest materials you can weld. Typically, when welding mild steel indoors, you can use a 75/25 Ar/CO2 mixture or 100% CO2, requiring a gas flow rate between 10–15 CFH.

However, you can increase the rate to 30 CFH if you notice any porosity on your welds.

When adjusting the shielding gas flow rate, consider your welding nozzle size.

- For nozzles smaller than ½ inches, the 10–15 CFH gas flow rate will be sufficient.

- If your nozzle is larger than ½ inches, it will require the flow rate to be between 18–55 CFH.

A helpful tip when MIG welding mild steel is to stay on the lower end of the recommended gas flow range when welding with a low speed while staying at the top end of that range when welding with high speeds.

Aluminum

It’s much easier to weld aluminum than stainless steel. As this material efficiently conducts heat, you’ll need to use high travel speeds during MIG welding. Because of that, a gas flow of 30 CFH might be the best option.

For welding aluminum, it’s typically best to use pure argon, but if the material is thick, you can use a shielding gas that combines argon and helium.

This shielding gas combination is much better for thick aluminum because helium improves penetration and enhances heat transfer.

However, when using a shielding gas containing argon and helium, you’ll need to increase the gas flow rate because helium is lighter than argon. The new shielding gas rate you’ll need will depend on how much helium the gas contains, and it could go up to 50 CFH.

Stainless Steel

Stainless steel is a durable material that frequently makes it hard to weld. While different factors will affect your weld, a proper shielding gas flow is essential for a high-quality weld.

When welding stainless steel, you’ll need to use a tri-mix shielding gas (10% Ar, 85-90% He+ 2-5% CO2), and it’s best to start by setting the gas flow between 25–30 CFH.

However, if needed, you should look for any signs of porosity and slightly increase the flow. Helium is lighter than carbon dioxide and argon, so porosity is bound to happen if you use an inadequate shielding gas flow rate.

You’ll need time to adjust and tweak the gas flow rate.

When working with a tri-mix shielding gas, it’s important to note that the amount of helium increases when you increase the gas flow. This may not seem like a big deal, but stainless steel doesn’t conduct heat as quickly as helium does.

Because of that, mismanaging heat and using too much helium could cause warping and carbide precipitation.

Learn more: MIG Welding Stainless Steel: A Beginners Guide

MIG Gas Flow Rate Chart – Flow Rates for Various Nozzle Sizes

The chart below depicts the minimum and maximum gas flow rates for standard MIG nozzle diameters for argon mixtures and CO2.

You should avoid exceeding the maximum recommended values to prevent air entrapment in the shielding gas.

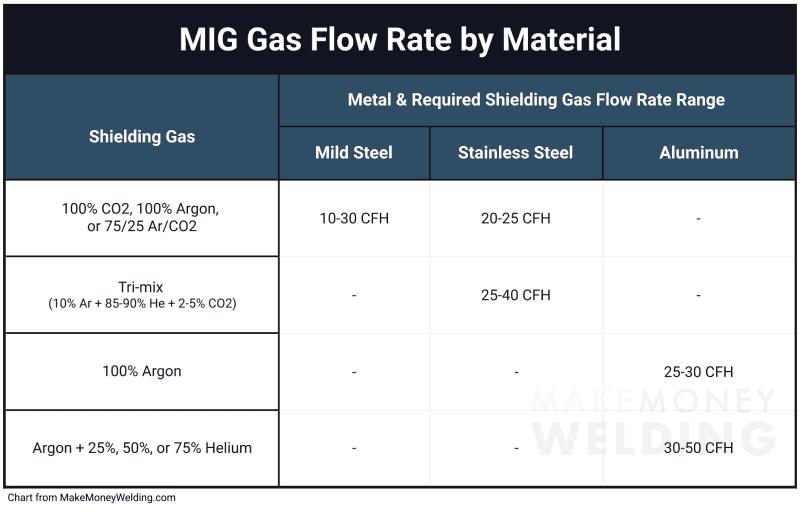

Summary Chart

Below is a chart depicting the estimates for the shielding gas flow rate based on the material you’re welding.

However, these values can vary depending on several things, including:

- Travel speed

- Welding position

- Joint configuration

- Wire feeding speed

- Material thickness

Click here for full size image

FAQ

How do I know when the gas is getting low in my tank?

Welding tanks have pressure and flow gauges, allowing you to see when your tank is low on gas. Once their level falls under the recommended amount, it’s time to replace your tank.

If you want to check the gas amount in your tank, simply look at the tank pressure gauge. There are other methods you can use to check the gas level, including weighing the tank, but they are more complex.

What will happen if the gas flow is too high?

Shielding gases are essential in MIG welding, allowing you to make successful welds. If the gas flow is too high, you’ll likely experience turbulence at the base of the gas nozzle for welding. If that happens, air will find its way into the welding gas flow, and you’ll risk atmospheric contamination, causing spatter, porosity, and inclusions.

What is the correct gas flow rate in liters per minute for MIG welding?

The correct gas flow rate for MIG welding in liters per minute (L/min) is typically between 4–14 L/min. However, in the same way, the gas flow rate varies in CFH; it also varies in L/min, mostly based on the welded material and the nozzle size.

Wrapping It Up

It’s important to understand MIG welding gas pressure so you can perform MIG welding successfully.

By using the gas flow recommendations from our article, you’ll be able to weld like a pro without risking the quality and reliability of your welds.

Make sure you adjust the gas flow rate when welding different materials, and don’t be afraid to make adjustments until you find that sweet spot that works for you.

I hope you’ve found this article helpful; feel free to share it with a fellow welding enthusiast!