If you’re wondering what a no gas MIG welder is, or how to MIG weld I’m going to show you that and a lot more.

A no gas MIG welder, also known as a flux core wire welder, is a simple process for beginners to learn how to weld with.

The awesome thing about no gas MIG welding is that you can start welding right out of the box when you buy a new wire welder. A wire welder is also known as a MIG welder.

The reason a no gas MIG welder works so well for beginners is that you don’t have to buy a gas cylinder to start welding with it, unlike MIG welding.

As I stated, a no gas MIG welder is the same thing as a flux core wire welder.

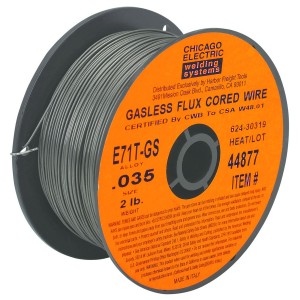

Flux core refers to the type of wire that the machine uses. When you install a roll of flux core wire in the machine and get your polarity set rights you are off to the races.

MIG Welding vs. No Gas MIG Welder

Beginners’ welding course instructors will start by telling you about wire.

Both the MIG welding process and the flux core process use what’s called a wire welding machine.

A wire welder differs from a process like stick welding because the electrode, the metal that melts to make the weld bead, comes on a roll of wire instead of a long steel rod.

With a MIG (Metal Inert Gas) welder once you pull the trigger of the gun to start the weld a few different things happen.

First off, when you have your gas bottle hooked up to your wire welder the gas starts flowing, the wire starts feeding, and the arc starts.

A no gas MIG welder doesn’t use gas, but rather a hollow wire that’s filled with flux. Flux is used to protect the molten weld puddle when it’s cooling. Just like flux is used to protect the weld puddle when using flux core wire, a shielding gas is used with the MIG process to protect the weld puddle.

The wire that’s used with the MIG process is a solid wire because no flux is needed.

So, don’t get the term ‘no gas MIG welder’ and ‘flux core welder’ confused because they are the same thing.

Related: Recommend No Gas MIG Welders – My Top Picks

Welding Outside With A No Gas MIG Welder

When using a no gas MIG welder you can weld in windy conditions with no problem.

So, if you’re working on a project outside and it’s a windy day, don’t worry because flux core is perfect for that.

What makes using a no gas MIG welder outside so good is that the wire has a flux inside and it creates a slag on top of the weld bead as it cools.

This slag protects the weld puddle from windy conditions and keeps the atmospheric gases off of the weld puddle.

The reason you can’t use MIG in windy conditions is that the shielding gas will get blown away, and you’ll be left with porosity in your welds.

Porosity is a bunch of holes that make your welds weak, so if you’re not using flux core wire then stay out of the wind.

Plus, a no gas MIG welder is more forgiving on dirty metals. When you’re welding with MIG you have to always make sure your metal is clean before you weld on it.

A no gas MIG welder is similar to a stick welder because both use flux, and flux allows you to get away with welding on dirtier metals.

That’s not to say you shouldn’t always clean your metal first, but a no gas MIG welder is more forgiving in that aspect.

Thank you for putting this article up,it’s very helpful I’m thinking of buying a mig welding machine and did not know the differences between gas and non gas types.